Essential Details

Taizhou Xiangrong Precision Technology Co.Ltd.is located in Zhejiang Huangyan Mold in telligent town. whichis known asthehometown ofmold Our sales and service center is located in No.625 Gongxin AvenueNorth City ofHuangyanthe central location of Zhejlang coastal industrialEconomiczonenorth to Ningbo,south to Wenzhou207 km away from Hangzhou. We mainly produce hieh-end steel castines CNCbladesStainless steel NC bladetitanium alloy NO blade,superalloysteel casting NCbladestain less steel NCbladeTitaniumalloy CNCturning blade and other cost-effectve cuttine tools Our company is committed to hieh hard materials.stainless steel materials. titanium alloy materi alshigh-temperature alloy materials and other difficult to process materials,So to support the research and development of cuttingtools provides enterprises with high-quality cutting tools and helps enterprises solve practical problems.| Blade Shape | Item No. | Item Size(mm) | Coated Carbide | ||||||||||

| L | ØI.C | S | Ød | r | XS2011 | MP2011 | JP6001 | PY8001 | SP6608 | GY8808 | WG01 | ||

| TNMG160404-MA | 16.5 | 9.525 | 4.76 | 3.81 | 0.4 | ★ | |||||||

| TNMG160408-MA | 8.7 | 9.525 | 4.76 | 3.81 | 0.8 | ★ | |||||||

| TNMG160412-MA | 8.7 | 9.525 | 4.76 | 3.81 | 1.2 | ★ | |||||||

| Blade Shape | Item No. | Item Size(mm) | Coated Carbide | ||||||||||

| | L | W | S | d | r | XS2011 | MP2011 | JP6001 | PY8001 | SP6608 | GY8808 | WG01 | |

| APMT1135PDER-M2 | 11.4 | 6.2 | 3.65 | 2.8 | 0.8 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | |

| APMT1604PDER-M2 | 17.26 | 9.24 | 4.76 | 4.4 | 0.5 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | |

| APMT1135PDER-H2 | 11.4 | 9.52 | 4.76 | 4.4 | 0.8 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | |

| APMT1604PDER-H2 | 17.25 | 9.52 | 4.76 | 4.4 | 0.8 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | |

Product description

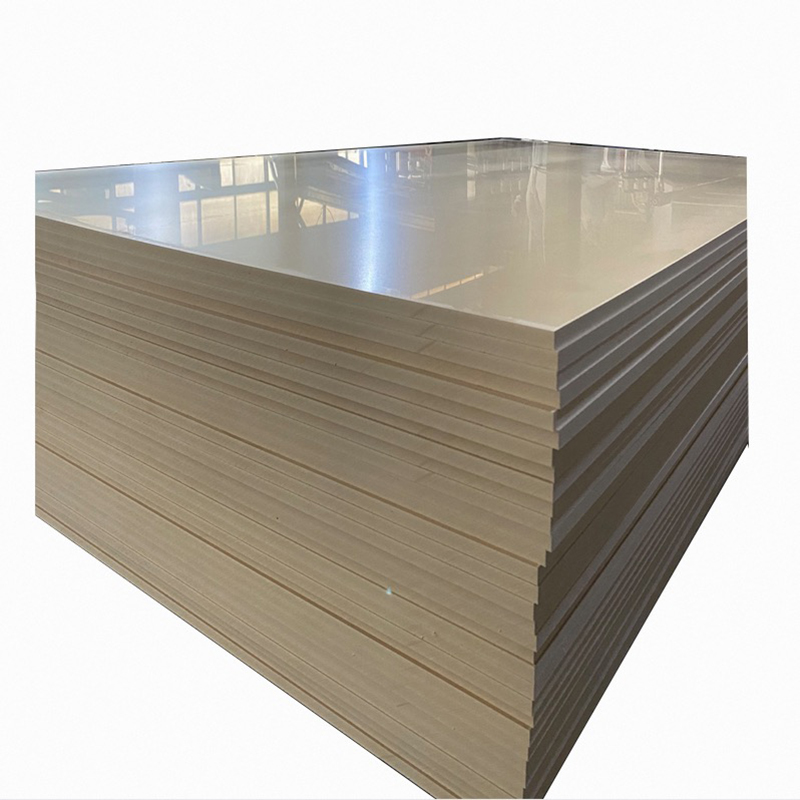

Product Packaging

TNMG160404-MA, TNMG160408-MA, TNMG160412-MA are a series of high-performance inserts, which are widely used in cutting metal materials. The following is a technical introduction and comparison of each type of blade: TNMG160404-MA Insert: This insert features precise tool geometry and edge parameters to ensure consistent cutting performance. The blade material is specially treated for excellent wear resistance, resisting wear and breakage. The blade adopts special coating technology to reduce friction and heat, improve cutting efficiency and tool life. TNMG160408-MA insert: This insert has been optimized in terms of tool geometry and cutting edge parameters. The insert material has premium hardness and can withstand high cutting loads. The surface of the blade is treated with a special coating, which reduces cutting friction and heat, reduces tool wear, and improves cutting accuracy and surface quality. TNMG160412-MA insert: This insert has specially optimized cutting geometry and edge parameters. The blade material is made of high-hardness alloy, which has excellent wear resistance and fracture resistance. The blade is specially coated to reduce friction and fusion during cutting, improving cutting efficiency and tool life. The common feature of TNMG160404-MA, TNMG160408-MA, and TNMG160412-MA inserts is that they are made of high-quality materials, with good cutting performance and wear resistance. The advantage of these inserts lies in the precise tool design and cutting edge parameters, making the cutting process more stable and efficient. The coating treatment technology of the blade can reduce the cutting force and temperature, prolong the life of the tool, and can improve the cutting accuracy and surface quality. In terms of difference, TNMG160404-MA inserts are suitable for fine cutting and high-precision machining; TNMG160408-MA inserts are suitable for general cutting and rough machining; TNMG160412-MA inserts are suitable for heavy cutting and high-load machining. Users can choose the appropriate blade model according to their specific needs to obtain the best cutting effect and processing quality. These inserts are widely used in manufacturing and processing industries, and can help users improve production efficiency and product quality.