High-Quality Hex Head Allen Wrench for Your Needs: A Comprehensive Guide

By:Admin

The tool industry is constantly evolving and innovating to meet the needs of professionals and DIY enthusiasts. One of the latest advancements in the industry comes in the form of the Hex Head Allen Wrench, which is set to revolutionize the way we tackle various projects. This unique tool, which has been developed by a leading company in the industry, promises to make tasks easier and more efficient, ultimately saving time and effort for individuals and businesses alike.

The Hex Head Allen Wrench is a multi-functional tool that is designed to provide users with the ability to tackle a wide range of jobs with ease and precision. Whether it’s assembling furniture, fixing machinery, or working on a construction project, this tool is built to handle it all. The innovative design of the wrench allows for a secure and precise grip, ensuring that tasks are completed with maximum efficiency and accuracy.

One of the key features of the Hex Head Allen Wrench is its durable construction, which is a result of the company’s commitment to quality and reliability. The wrench is made from high-quality materials that are designed to withstand the rigors of everyday use, making it a dependable tool for professionals and hobbyists alike. In addition, the wrench is designed to be ergonomic and user-friendly, making it comfortable to use for extended periods of time without causing fatigue or discomfort.

The Hex Head Allen Wrench also boasts a unique and versatile design that sets it apart from traditional wrenches. Its hexagonal head allows for easy insertion and removal from fasteners, while its compact size makes it ideal for use in tight spaces. This versatility makes the wrench a valuable addition to any toolbox, as it can be used in a variety of applications without the need for multiple tools.

This innovative tool is just one example of the company's dedication to providing top-quality tools and equipment to professionals and enthusiasts. With a long-standing reputation for excellence in the industry, the company has earned the trust and loyalty of customers around the world. By consistently delivering high-quality products that are designed to meet the needs of the modern worker, the company has established itself as a leader in the industry.

The launch of the Hex Head Allen Wrench is a testament to the company's commitment to innovation and excellence. Through extensive research and development, the company has been able to create a tool that addresses the needs of today’s professionals and hobbyists. By combining cutting-edge technology with a deep understanding of the industry, the company has succeeded in developing a tool that is set to become an essential part of every toolbox.

As the tool industry continues to evolve, the Hex Head Allen Wrench is poised to become a game-changer. Its innovative design, durable construction, and versatile functionality make it a must-have for anyone looking to tackle projects with ease and precision. With the backing of a reputable company known for delivering top-quality products, the Hex Head Allen Wrench is set to become a staple in the industry for years to come. Whether you’re a professional or a hobbyist, this tool is sure to become an indispensable companion for all your projects.

Company News & Blog

High-Quality Carbide Inserts 1204 for Precision Machining

Mitsubishi Carbide Inserts 1204: The Cutting Edge of Precision and EfficiencyIn the world of manufacturing and engineering, precision and efficiency are key factors in achieving high-quality and cost-effective production. With the advancement of technology and innovation, companies are constantly in search of high-performance tools that can improve their processes and ultimately contribute to their success in the industry.One such company that has been at the forefront of providing cutting-edge solutions for the manufacturing sector is Mitsubishi Materials Corporation. With a history spanning over a century, Mitsubishi Materials has established itself as a global leader in the development and production of advanced materials, tools, and equipment for a wide range of industries, including automotive, aerospace, energy, and more.One of the flagship products of Mitsubishi Materials is the Carbide Inserts 1204, which has gained a reputation for its exceptional performance and reliability in various machining applications. These inserts are part of Mitsubishi Materials' comprehensive lineup of cutting tools, designed to meet the diverse needs of modern manufacturing processes.The Mitsubishi Carbide Inserts 1204 are engineered to deliver precision cutting and superior surface finish, making them an ideal choice for a wide range of materials, including steel, stainless steel, cast iron, and non-ferrous metals. The inserts are designed with a unique geometry and advanced coating technology, resulting in extended tool life and enhanced productivity for machinists and manufacturers.One of the key features of the Mitsubishi Carbide Inserts 1204 is their versatility, allowing for a wide range of cutting operations, including turning, milling, and boring. This flexibility makes them a valuable asset for machine shops and production facilities, where efficiency and quick changeover are essential for meeting tight production schedules and delivering high-quality parts.Furthermore, Mitsubishi Materials offers a comprehensive technical support system to assist customers in optimizing their machining processes and maximizing the performance of the Carbide Inserts 1204. With a team of experienced engineers and application specialists, the company provides valuable insights and recommendations to help customers achieve the best results in their specific applications.The commitment to quality and innovation is deeply rooted in Mitsubishi Materials' corporate philosophy, which emphasizes the pursuit of excellence and continuous improvement in product development and customer satisfaction. This philosophy is reflected in the stringent quality control measures and advanced manufacturing techniques employed in the production of the Carbide Inserts 1204, ensuring that they meet the highest standards of performance and reliability.In addition to the Carbide Inserts 1204, Mitsubishi Materials offers a wide range of cutting tools, including end mills, drills, and indexable inserts, to cater to the evolving needs of the manufacturing industry. The company's dedication to research and development has led to the introduction of new and innovative products that address the challenges of the modern machining environment, such as high-speed and high-feed machining, as well as hard-to-cut materials.As the manufacturing industry continues to embrace digitalization and automation, Mitsubishi Materials is also at the forefront of providing smart solutions that integrate cutting-edge technologies, such as IoT (Internet of Things) and AI (Artificial Intelligence), into its products and services. This strategic approach not only enhances the performance of the Carbide Inserts 1204 but also enables customers to optimize their overall production processes and achieve higher levels of efficiency and profitability.In conclusion, Mitsubishi Materials Corporation stands as a leading provider of advanced cutting tools and solutions, with the Carbide Inserts 1204 exemplifying the company's commitment to innovation, quality, and customer satisfaction. With their precision, versatility, and reliability, these inserts have become a trusted choice for manufacturers and machinists seeking to achieve enhanced productivity and superior results in their machining operations. As the manufacturing industry continues to evolve, Mitsubishi Materials remains dedicated to driving progress and setting new standards for excellence in cutting tool technology.

Carbide Insert: High-Quality and Durable Tool for Various Applications

Lamina Carbide Insert, a leading manufacturer of high-quality carbide cutting tools, has recently introduced a new and innovative line of carbide inserts designed to meet the ever-growing demands of the machining industry. With a focus on precision, durability, and efficiency, these new carbide inserts have been engineered to deliver optimal performance in a wide range of machining applications.Lamina Carbide Insert has been at the forefront of cutting tool technology for over 50 years, consistently setting the standard for excellence in the industry. With a strong commitment to research and development, the company continuously seeks to innovate and improve upon its products, in order to provide its customers with the most advanced cutting solutions available.The new line of carbide inserts is the result of extensive research and development efforts, aimed at addressing the specific needs and challenges faced by machinists in today's fast-paced manufacturing environment. Recognizing the importance of versatility, the inserts have been designed to deliver exceptional performance across various materials, including steel, stainless steel, cast iron, and non-ferrous metals.One of the key features of the new carbide inserts is their advanced cutting edge geometry, which has been carefully optimized to ensure smooth and efficient chip removal, as well as reduced cutting forces. This results in improved surface finishes, extended tool life, and increased productivity for the end user. Additionally, the inserts incorporate a specialized coating that enhances wear resistance and heat dissipation, further contributing to their overall performance and longevity.In keeping with Lamina Carbide Insert's commitment to quality and precision, the new inserts undergo rigorous testing and quality control measures to ensure dimensional accuracy and consistency across the entire product line. This dedication to excellence has earned the company a reputation for reliability and performance, making it a trusted partner for machinists and manufacturers worldwide.Furthermore, Lamina Carbide Insert's extensive range of carbide inserts is compatible with a variety of cutting tool systems, offering customers the flexibility to choose the best solution for their specific machining needs. Whether it's turning, milling, threading, or grooving, the company's comprehensive product offering ensures that customers can find the perfect insert to optimize their machining operations.As a global leader in the cutting tool industry, Lamina Carbide Insert is dedicated to providing comprehensive support and technical expertise to its customers. The company's team of experienced engineers and applications specialists are readily available to assist with tool selection, application optimization, and troubleshooting, ensuring that customers can confidently achieve their machining objectives.With the introduction of its new line of carbide inserts, Lamina Carbide Insert demonstrates its ongoing commitment to advancing cutting tool technology and supporting the evolving needs of the machining industry. By combining precision engineering, advanced materials, and a steadfast dedication to customer satisfaction, the company continues to set the standard for excellence in the manufacturing sector.In conclusion, with a rich history of innovation and a relentless pursuit of excellence, Lamina Carbide Insert remains a trusted and respected name in the cutting tool industry. The company's new line of carbide inserts exemplifies its unwavering dedication to providing high-quality, high-performance solutions for the modern machining professional. As the manufacturing landscape continues to evolve, customers can rely on Lamina Carbide Insert to deliver the cutting-edge tools and technical expertise needed to stay ahead of the curve.

High Precision End Mill Sharpening Machine for Your Business Needs

Today, we are excited to announce the launch of our latest innovation, the End Mill Sharpening Machine. This cutting-edge machine is set to revolutionize the industry by providing precision sharpening for end mills, saving time and improving productivity for our customers.The End Mill Sharpening Machine is equipped with advanced technology that ensures accurate and consistent sharpening of end mills, giving them a new lease of life and prolonging their usage. This machine is user-friendly, with an intuitive interface that allows for easy setup and operation, making it suitable for both experienced machinists and those new to end mill sharpening.Our company, with a history of more than 20 years in the industry, has always been at the forefront of innovation and technology. We have a strong track record of delivering high-quality products and solutions to our customers, and the End Mill Sharpening Machine is no exception. With our commitment to continuous improvement and customer satisfaction, we have designed this machine to meet the evolving needs of the industry and to provide our customers with a competitive edge.The End Mill Sharpening Machine is designed to address the common challenges faced by machinists when it comes to end mill maintenance. Keeping end mills sharp and in optimal condition is crucial for achieving high-quality machining results, and our machine offers a cost-effective and efficient solution to this. With the ability to sharpen a wide range of end mill sizes and types, our machine caters to the diverse needs of our customers and ensures that their end mills are always in top working condition.In addition to its technical capabilities, the End Mill Sharpening Machine is also designed with durability and longevity in mind. We understand that our customers rely on their equipment to withstand heavy usage and to deliver consistent results, and our machine is built to meet these demands. With high-quality components and a robust construction, our machine is designed to withstand the rigors of daily use and to provide reliable performance for years to come.We are also proud to highlight the sustainability benefits of our End Mill Sharpening Machine. By extending the lifespan of end mills through precision sharpening, our machine contributes to the reduction of waste and the conservation of resources. This aligns with our company's commitment to environmental responsibility and our efforts to support sustainable practices within the industry.As part of our commitment to customer satisfaction, we are also offering comprehensive training and support for the End Mill Sharpening Machine. Our team of technical experts is available to provide guidance on machine setup, operation, and maintenance, ensuring that our customers can maximize the benefits of this innovative solution. We are dedicated to supporting our customers every step of the way and to ensuring that they experience the full potential of our products.In conclusion, the launch of the End Mill Sharpening Machine represents a significant milestone for our company and for the industry as a whole. This machine embodies our dedication to delivering cutting-edge solutions that address the evolving needs of our customers, while also prioritizing quality, durability, and sustainability. We are confident that the End Mill Sharpening Machine will empower our customers to elevate their machining capabilities and to achieve greater success in their operations.We are excited to bring this innovative solution to the market and to continue serving as a trusted partner for our customers' success. With the End Mill Sharpening Machine, we are shaping the future of end mill maintenance and redefining industry standards.

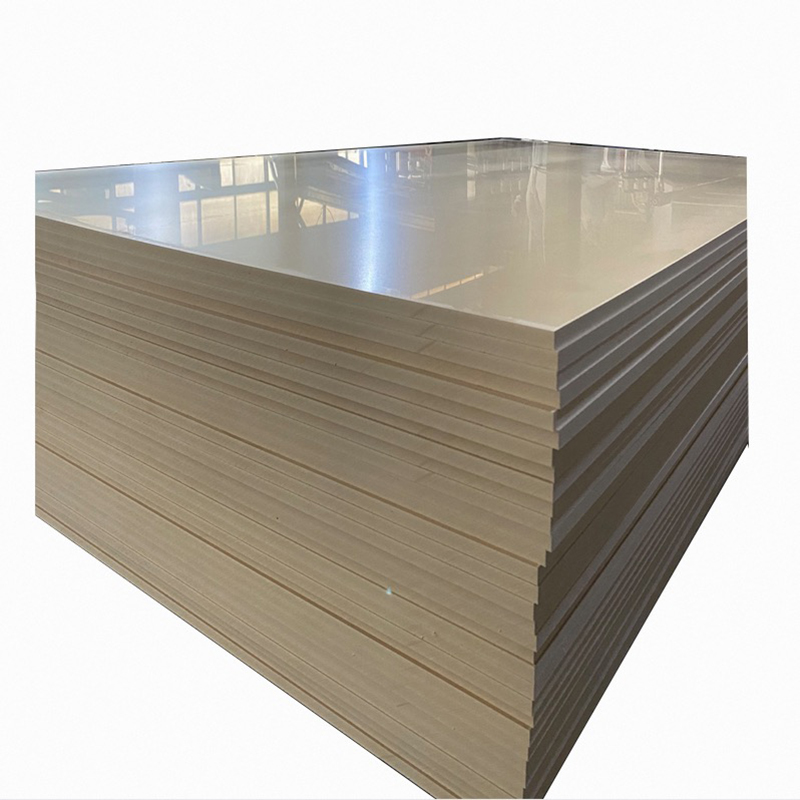

Foamex Sizes Suppliers in China: Everything You Need to Know

China Foamex Sizes Suppliers Boosting Production to Meet Growing DemandAs the demand for foam products continues to rise globally, China Foamex Sizes Suppliers has announced a significant increase in their production capacity to meet the growing market needs. The company, which specializes in manufacturing and supplying foam products of various sizes and specifications, has seen a surge in demand for their products in recent years. This expansion comes as a response to the increasing need for foam materials in various industries, including packaging, construction, automotive, and many others.With the continuous growth of the global economy, the demand for foam products has been on the rise. This trend has been further accelerated by the increasing awareness of the benefits of foam in various applications. Foam products are widely used for their lightweight, insulating, cushioning, and protective properties, making them essential in a wide range of industries. As a result, China Foamex Sizes Suppliers has recognized the need to enhance their production capabilities to meet the growing demand from their customers.The company has invested heavily in expanding their manufacturing facilities, acquiring new machinery and equipment, and implementing advanced production technologies to increase their productivity. This strategic move will not only allow China Foamex Sizes Suppliers to meet the current demand but also prepare them for future growth opportunities. By boosting their production capacity, the company aims to ensure a steady and reliable supply of high-quality foam products to their customers, both in domestic and international markets.In addition to expanding their production capacity, China Foamex Sizes Suppliers has also focused on enhancing the quality and diversity of their product range. The company offers foam products in a wide variety of sizes, densities, and specifications to cater to the specific needs of different industries. Their foam materials are highly versatile and can be customized to meet the unique requirements of their customers. With a strong focus on innovation and product development, the company continues to introduce new and improved foam solutions to address the evolving needs of the market.Moreover, China Foamex Sizes Suppliers has established a robust quality control system to ensure that all their products meet the highest standards of performance, durability, and safety. The company adheres to strict quality management practices throughout the production process, from raw material procurement to final product inspection. This commitment to quality has earned China Foamex Sizes Suppliers a strong reputation for reliability and consistency among their customers and partners.Furthermore, the company has been actively promoting sustainability and environmental responsibility in their operations. China Foamex Sizes Suppliers recognizes the importance of minimizing their environmental footprint and has taken steps to implement eco-friendly practices in their manufacturing processes. They are dedicated to reducing waste, conserving energy, and utilizing recyclable materials to produce their foam products. By aligning their business practices with sustainable principles, the company aims to contribute to a greener and more sustainable future.With their expanded production capacity, diversified product range, and commitment to quality and sustainability, China Foamex Sizes Suppliers is well-positioned to meet the growing demand for foam products in the global market. The company's efforts to enhance their manufacturing capabilities demonstrate their dedication to providing exceptional products and services to their customers. As the demand for foam continues to grow, China Foamex Sizes Suppliers remains committed to being a reliable and trusted partner for businesses seeking high-quality foam solutions.

Durable 10mm PVC Sheet for Various Applications

The demand for high-quality PVC 10mm sheets has been on the rise in various industries, and one company has been leading the way in providing top-notch products to meet this demand. With an unwavering commitment to excellence and innovation, [company name] has become a trusted name in the field of PVC sheet manufacturing.[Company name] has a long-standing reputation for producing PVC 10mm sheets that are not only durable and versatile but also environmentally friendly. Their commitment to sustainability and reducing their carbon footprint has set them apart in the industry. The company has invested in state-of-the-art technology and manufacturing processes to ensure that their products meet the highest standards of quality and performance.The PVC 10mm sheets manufactured by [company name] are widely used in a variety of applications, including construction, automotive, signage, and display. These sheets are known for their excellent strength, impact resistance, and UV stability, making them an ideal choice for outdoor and indoor use. Moreover, the company offers a wide range of colors and finishes to cater to the diverse needs of its customers.Recognizing the growing demand for PVC 10mm sheets in the market, [company name] has continued to expand its production capacity and enhance its product offerings. The company has a team of skilled engineers and technicians who are dedicated to developing innovative solutions and pushing the boundaries of PVC sheet technology. This relentless pursuit of excellence has positioned [company name] as a leader in the industry.In addition to its commitment to quality and innovation, [company name] also prioritizes customer satisfaction. The company works closely with its clients to understand their specific requirements and deliver customized solutions that meet their needs. Whether it's a large-scale construction project or a small-scale signage application, [company name] ensures that its customers receive the right PVC 10mm sheets for their application.Furthermore, [company name] places a strong emphasis on sustainability and environmental responsibility. The company uses eco-friendly materials and processes in its manufacturing operations, and it constantly looks for ways to reduce waste and minimize its environmental impact. This commitment to sustainability has not only earned [company name] the trust of its customers but has also positioned the company as a responsible corporate citizen.Looking ahead, [company name] is poised to continue its growth and expansion in the PVC sheet market. The company remains dedicated to pushing the boundaries of innovation and sustainability and aims to set new benchmarks for product quality and performance. With a strong focus on customer satisfaction and a relentless pursuit of excellence, [company name] is well-positioned to meet the evolving needs of the industry and maintain its leadership position in the market.In conclusion, [company name] has established itself as a leader in the manufacturing of PVC 10mm sheets, thanks to its unwavering commitment to quality, innovation, and customer satisfaction. The company's dedication to sustainability and environmental responsibility further underscores its status as a trusted and respected player in the industry. As the demand for high-quality PVC sheets continues to grow, [company name] is well-equipped to meet the needs of its customers and lead the way in the market.

Durable and Versatile 19mm PVC Board for Various Applications

The 19mm PVC board has become a popular choice in the construction industry due to its versatility and durability. This versatile material is commonly used in various applications such as furniture, construction, and interior design. One of the leading manufacturers of 19mm PVC board is {} which has gained a strong reputation for producing high-quality PVC boards that meet the requirements of modern construction projects. The company has been in the industry for over a decade and has established itself as a reliable supplier of PVC boards for commercial and residential use.{} offers a wide range of PVC boards, including the 19mm thickness option, which is ideal for applications that require enhanced strength and durability. The boards are manufactured using advanced technology and high-quality raw materials to ensure consistent quality and performance. The 19mm PVC board from {} is known for its excellent impact resistance, weather resistance, and low maintenance requirements, making it a popular choice among builders and designers. The boards are also lightweight and easy to install, saving time and labor costs on construction projects.In addition to its physical properties, the 19mm PVC board from {} is also environmentally friendly, as it is 100% recyclable and does not contain any harmful chemicals. This makes it a sustainable choice for projects that require green building materials.The company takes pride in its commitment to quality and customer satisfaction. {} has a team of skilled professionals who oversee the manufacturing process to ensure that all products meet the highest standards. The company also has a dedicated customer service team that provides technical support and assistance to clients, ensuring a smooth and hassle-free experience.With a strong emphasis on innovation, {} continues to invest in research and development to improve its products and explore new applications for PVC boards. The company is constantly expanding its product range to meet the evolving needs of the construction industry, staying ahead of the curve with the latest trends and technologies.{} has also established a strong distribution network, ensuring that its 19mm PVC boards are readily available to customers worldwide. The company has built long-term partnerships with distributors and retailers, making it easy for builders and designers to access their products and benefit from their reliability and performance.In conclusion, the 19mm PVC board from {} is a versatile and durable solution for a wide range of construction applications. With its exceptional physical properties, environmental friendliness, and commitment to quality, {} has earned a strong reputation as a leading supplier of PVC boards in the industry. As the construction industry continues to evolve, {} is well-positioned to meet the demands for high-quality, sustainable building materials, driving innovation and delivering value to its customers.

Exploring the Emerging Market of Foamex Sheets Factories in China

Title: China's Foamex Sheets Factories: Leading the Way in Foam Manufacturing Innovation Introduction:With China's booming manufacturing sector, the country has carved a significant niche for itself in various industries. One such industry that has witnessed exceptional growth and innovation is the foam manufacturing industry. Among the leading players in this sector are China's top foam manufacturing companies, including the renowned Foamex Sheets Factories. This article will delve into the innovative practices of Foamex Sheets Factories, shedding light on their commitment to quality, sustainability, and cutting-edge foam manufacturing techniques.I. Company Overview and Vision:Foamex Sheets Factories, located in the heart of China's thriving manufacturing region, is a prominent player in the foam manufacturing industry. With a rich history dating back several decades, the company has solidified its position as a leader in providing high-quality foam products to a wide range of industries, including automotive, construction, packaging, and furniture.Driven by a vision to revolutionize the foam manufacturing landscape, Foamex Sheets Factories continually invests in research and development to deliver innovative solutions. The company's core values revolve around quality, durability, sustainability, and customer satisfaction.II. Advanced Manufacturing Techniques and Equipment:Foamex Sheets Factories prides itself on employing state-of-the-art manufacturing techniques and equipment to ensure exceptional product quality and consistency. The facilities are equipped with cutting-edge foam extrusion and lamination lines, enabling them to produce an extensive range of foam products with precision and efficiency.The adoption of computer-controlled manufacturing processes ensures minimal material waste and enhanced foam structure uniformity. This commitment to technological advancement has propelled Foamex Sheets Factories to the forefront of the industry.III. Commitment to Quality Assurance:Foamex Sheets Factories places great emphasis on maintaining stringent quality control measures throughout the manufacturing process. By adhering to international standards and certifications, the company guarantees that its foam products adhere to the highest levels of quality, safety, and performance.To further reinforce their commitment to quality, the company conducts rigorous testing at every stage, from raw material selection to the final product. Foamex Sheets Factories' dedicated quality control team carries out meticulous inspections, ensuring that each foam product meets or exceeds industry standards.IV. Sustainable Manufacturing Practices:In line with the global shift towards sustainability, Foamex Sheets Factories prioritizes eco-friendly manufacturing practices. The company actively seeks ways to reduce its carbon footprint by optimizing energy consumption, minimizing waste generation, and adopting environmentally-friendly materials.Foamex Sheets Factories utilizes advanced recycling techniques to transform waste foam into reusable products, contributing to the circular economy. By actively promoting sustainable practices, the company shows its unwavering commitment to preserving the environment for future generations.V. Market Expansion and Global Reach:Recognizing the growing global demand for foam products, Foamex Sheets Factories has strategically expanded its market reach. The company has established a strong distribution network, allowing it to provide foam solutions to customers worldwide. With a customer-centric approach, Foamex Sheets Factories ensures timely delivery and excellent customer service, building lasting relationships with clients across the globe.VI. Collaborative Partnerships and Innovation:Foamex Sheets Factories actively collaborates with research institutions, universities, and industry experts to drive innovation. By sharing knowledge and resources, the company remains at the forefront of foam manufacturing technology. These collaborative efforts enable the development of new foam products that cater to ever-evolving market needs.Conclusion:Driven by a commitment to quality, sustainability, and innovation, Foamex Sheets Factories has emerged as a leading force in China's foam manufacturing industry. Its advanced manufacturing techniques, unwavering commitment to quality control, sustainable practices, and global presence have propelled the company to the forefront of the market. With an eye towards the future, Foamex Sheets Factories is set to continue revolutionizing the foam manufacturing industry with its dedication to excellence and customer satisfaction.

Different Types of Whipper Snipper Head to Consider

Choosing the right whipper snipper head type for your gardening needs can make a world of difference in the ease and efficiency of your landscaping tasks. With a variety of head types available, it can be overwhelming to know which one is best for your specific needs. In this article, we'll take a look at the different whipper snipper head types available from various manufacturers, including the options offered by a leading gardening equipment company.When it comes to gardening and landscaping equipment, one company that stands out is known for its high-quality products and innovative designs. With a strong reputation for reliability and performance, this company offers a range of gardening tools and equipment to suit the needs of both homeowners and professionals alike.One of the standout products offered by this company is their line of whipper snippers, which are designed to make trimming grass and weeds a breeze. The company understands that different users have different needs, which is why they offer a variety of head types for their whipper snippers to cater to a wide range of gardening tasks.For instance, one of the most popular head types offered by this company is the brush cutter head. This type of head is ideal for those who need to tackle thick patches of grass and weeds, as well as light brush and small saplings. The brush cutter head is designed to be durable and efficient, making it the perfect choice for more heavy-duty gardening tasks.Another popular whipper snipper head type offered by this company is the line trimmer head. This type of head is perfect for everyday lawn maintenance, as it allows for precise trimming around borders, trees, and other obstacles. The line trimmer head is easy to use and provides a clean and neat finish to any lawn.In addition to these two main head types, this company also offers a range of other attachments and accessories for their whipper snippers, including edger attachments and hedge trimmer attachments. These options allow users to customize their whipper snippers to suit their specific gardening needs, making it a versatile and valuable tool to have in the shed.The company's commitment to innovation and quality is evident in the performance of their whipper snipper head types. Each head type is carefully designed and tested to ensure it meets the highest standards of performance and durability. Users can have confidence in the reliability of these head types, knowing that they are backed by a company with a strong reputation for excellence in the gardening and landscaping industry.Furthermore, the company provides comprehensive support and customer service to assist users in selecting the right whipper snipper head type for their needs. Whether it's through online resources, product demonstrations, or expert advice, the company is dedicated to helping users make informed decisions about their gardening equipment.In conclusion, the choice of whipper snipper head type can greatly impact the ease and efficiency of your gardening tasks. With a range of high-quality and reliable head types available from a leading gardening equipment company, users can find the perfect solution for their specific needs. Whether it's a brush cutter head for heavy-duty tasks or a line trimmer head for everyday lawn maintenance, this company has the right options to make gardening a more enjoyable and rewarding experience.

High-Quality 3mm CNC End Mill Bit for Precision Milling

title: Leading CNC Company Introduces New 3mm End Mill Bit for Precision MachiningIn the world of advanced machining, precision is key. That's why [company name], a leading manufacturer of CNC tools and equipment, has recently introduced a new 3mm End Mill Bit to their product lineup. This cutting-edge tool is set to revolutionize the industry by offering unparalleled precision and efficiency in machining processes.With over [number] years of experience in the CNC machining industry, [company name] has established itself as a trusted name in the business. Their commitment to innovation and quality has earned them a reputation for excellence among their clients and partners. The introduction of the new 3mm End Mill Bit is a testament to their dedication to providing their customers with the best tools for their machining needs.The 3mm End Mill Bit is designed for use in a wide range of materials, including aluminum, steel, and plastics. Its precise cutting edges and high-quality construction make it ideal for intricate machining tasks that require a high level of accuracy. Whether used in a small workshop or a large-scale manufacturing facility, this new tool is sure to deliver exceptional results.One of the key features of the 3mm End Mill Bit is its advanced coating technology, which provides enhanced wear resistance and prolongs the tool's lifespan. This means that machinists can rely on this new end mill bit to maintain its sharpness and precision over a longer period, resulting in cost savings and improved efficiency.In addition to its exceptional performance, the 3mm End Mill Bit is also designed with user convenience in mind. Its shank is compatible with a wide range of CNC machines, making it easy for machinists to integrate into their existing equipment. Furthermore, [company name] provides comprehensive technical support and guidance to ensure that their clients are able to maximize the potential of this new tool.The introduction of the 3mm End Mill Bit is a significant milestone for [company name] and a testament to their ongoing commitment to innovation. By continuously investing in research and development, [company name] is able to stay ahead of the curve and anticipate the evolving needs of the machining industry. This new product is just one example of their dedication to providing cutting-edge solutions to their clients.To promote the launch of the 3mm End Mill Bit, [company name] will be offering demonstrations and workshops to showcase its capabilities. This hands-on approach will allow machinists to experience the performance of the new tool firsthand and gain a better understanding of how it can benefit their operations.As the machining industry continues to evolve, the demand for precision tools will only increase. The introduction of the 3mm End Mill Bit is a clear reflection of [company name]'s vision to meet this demand and provide their clients with the best solutions available. With its unparalleled precision, durability, and user-friendly design, this new tool is set to make a significant impact in the world of CNC machining.In conclusion, the introduction of the 3mm End Mill Bit by [company name] represents a significant advancement in the machining industry. With its cutting-edge technology and precision engineering, this new tool is poised to set a new standard for accuracy and efficiency in machining processes. As the industry continues to evolve, [company name] remains committed to providing their clients with the best tools and solutions available, and the 3mm End Mill Bit is a shining example of their dedication to innovation.

High-Quality 3mm CNC End Mill Bit for Precision Machining

{Company Name}, a leading manufacturer in the machining industry, has unveiled its latest innovation in cutting tools, the CNC end mill bit 3mm. This new addition to their extensive lineup of cutting tools is set to revolutionize the precision machining industry with its superior quality and performance.With over 20 years of experience in the manufacturing of cutting tools, {Company Name} has established itself as a pioneer in the industry. The company prides itself on its unwavering commitment to producing high-quality products that meet the ever-evolving needs of the machining industry. Their state-of-the-art manufacturing facility is equipped with the latest technology and a team of highly skilled engineers and technicians who are dedicated to pushing the boundaries of innovation.The newly launched CNC end mill bit 3mm is a testament to {Company Name}'s dedication to excellence. Designed for precision machining, this cutting tool is engineered to deliver exceptional performance and durability. The 3mm diameter makes it suitable for a wide range of applications, from fine detail work to heavy-duty machining. Its advanced design ensures smooth and stable cutting, allowing for high precision and superior surface finish.One of the key features of the CNC end mill bit 3mm is its exceptional cutting edge sharpness, which is achieved through {Company Name}'s advanced grinding technology. This ensures that the tool maintains its cutting performance over an extended period of use, providing cost-effective and reliable machining solutions for their customers.In addition to its cutting-edge design, the CNC end mill bit 3mm is manufactured from high-quality materials, further enhancing its performance and longevity. {Company Name} uses only the finest carbide materials in the production of their cutting tools, ensuring superior strength and wear resistance. This allows the end mill bit to withstand the rigors of high-speed machining while maintaining its sharpness and precision.The launch of the CNC end mill bit 3mm underscores {Company Name}'s commitment to innovation and customer satisfaction. They understand the importance of providing their customers with cutting-edge tools that enable them to stay ahead in the competitive machining industry. By continuously investing in research and development, {Company Name} remains at the forefront of technological advancement, offering cutting tools that meet the highest standards of quality and performance.As a company that prioritizes customer needs, {Company Name} also offers customized solutions for clients with specific machining requirements. Their team of experts works closely with customers to understand their unique challenges and develop tailored cutting tool solutions that address their specific needs.The introduction of the CNC end mill bit 3mm is a reflection of {Company Name}'s ongoing efforts to provide the machining industry with innovative and reliable cutting tools. With its superior quality, precision, and durability, this new addition to their product range is poised to set a new standard in the world of precision machining.In conclusion, {Company Name} continues to solidify its position as a leader in the machining industry with the launch of the CNC end mill bit 3mm. Their unwavering commitment to excellence and innovation is evident in the quality and performance of their cutting tools. As they continue to push the boundaries of technological advancement, {Company Name} is set to shape the future of precision machining with cutting-edge solutions that empower their customers to achieve their manufacturing goals.